While half the global population relies on rice as a staple, about 15 percent of rice produced each year is contaminated by potentially fatal aflatoxins. Seeing this threaten lives in her home country of Kenya prompted a graduate research assistant to focus on eradicating the risk through safer storage methods.

Faith Ouma, a Ph.D. student in the food science department at the University of Arkansas, was the lead author of “Investigating safe storage conditions to mitigate aflatoxin contamination in rice.” It was published in Food Control, an international food safety journal.

READ MORE: Researchers find unique adaptations of fungus associated with bee bread

READ MORE: Analysis of flour and rice in Brazil shows high levels of harmful fungal toxins

Ouma completed her undergraduate studies in biochemistry in Kenya before earning a master’s and pursuing a doctoral degree at the University of Arkansas. Her study was conducted through the Arkansas Agricultural Experiment Station, the research arm of the University of Arkansas System Division of Agriculture. The food science department is part of the Dale Bumpers College of Agricultural, Food and Life Sciences.

Fungal contamination

When exposed to poor storage conditions such as high temperatures and humidity, rice can become contaminated with fungi. Fungi can then produce naturally occurring toxic compounds called mycotoxins though researchers have yet to discover why they create the toxins. Aflatoxins, a family of mycotoxins, are poisonous compounds that have been designated by the International Agency for Research on Cancer as Group 1 carcinogens, meaning there is sufficient evidence they can cause cancer in humans. Aflatoxins also pose a greater risk to children by threatening their immune systems and growth.

“Aflatoxins in the U.S. are not much of a big problem because of development,” Ouma said. “But where I come from in Kenya, it is one of the hotspots. There was a time people died because they consumed corn contaminated with aflatoxins.”

According to research published in 2020 by the Journal of Young Investigators, in 2004, Kenya saw the most extreme aflatoxin outbreak in the world, which included 317 cases and 125 deaths.

Griffiths Atungulu, food science associate professor and director of the Arkansas Rice Processing Program, serves as Ouma’s adviser and co-author. Other co-authors included Kaushik Luthra, a food science postdoctoral fellow, and Abass Oduola, a former food science doctoral student.

Research objective

The project is part of Ouma’s larger research objective on the safety of ready-to-eat rice products, such as instant rice, that she will maintain as she pursues her doctorate. For her rice safety research, she earned the first-place award from the Arkansas Association for Food Protection for her poster in the Interventions, Pre- and Post-Harvest division in 2022. She was also recognized as outstanding presenter at the American Society of Agricultural and Biological Engineers Annual International Meeting for her oral presentation the same year.

Aflatoxin contamination poses an even greater risk with products such as instant rice and rice cakes. Atungulu noted that a producer’s window for mitigating this risk is in the early stages of rice processing. In later processing to create products such as instant rice and rice cakes, even high temperatures reaching 200 degrees Celsius, or 392 degrees Fahrenheit, won’t eliminate aflatoxins once they are produced. Even if high temperatures were effective in destroying the aflatoxin, they would likely degrade nutritional quality.

“Once the toxin’s been formed, the grain becomes almost useless,” Atungulu said.

Investigating growth conditions

Researchers set out to understand how to prevent aflatoxin formation by measuring how temperature, humidity, storage time and moisture impacted the toxin’s growth.

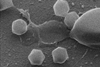

Rice from a farm in Hazen was collected and divided into rough, brown and milled rice fractions. Rough rice is unprocessed and still has its hull, or hard protective covering, while brown rice does not. Milled rice has its hull and bran layers removed. Samples of each type of rice were then divided into autoclaved, or steam-sterilized, and non-autoclaved. All samples were inoculated with Aspergillus flavus, a type of fungus that produces aflatoxins, and the team then tracked aflatoxin levels.

“We were looking at what the environments are that would make these fungi feel so confident to start producing the toxin,” Atungulu said.

Toxin presence

The researchers measured ergosterol, a substance in the fungus cell walls, and the quantity of Aflatoxin B1, a potent toxin linked to liver cancer and immune system suppression. Researchers found that temperature and relative humidity levels had the most significant impacts on fungal growth, and they had an even greater impact when present together. They also found that brown rice had notably high Aflatoxin B1 levels due to the fats in its bran, which can provide carbon for increased fungal growth and aflatoxin production.

Ouma’s study showed that proper rice storage conditions to reduce aflatoxin risk after harvest include a temperature below 20 degrees Celsius, or 68 degrees Fahrenheit, and relative humidity below 75 percent. While the research involved careful measurements of fungal and aflatoxin levels at various temperatures, humidity levels, and other parameters, Ouma said she hopes the impact of her work is twofold.

“As much as I want to publish data, I also want to come up with something that can help solve a real-world problem when I go back home,” Ouma said.

No comments yet