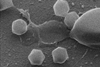

Microbial organisms adapted to extreme and inhospitable environments carry proteins within their proteome that significantly accelerate the dissolution of CO₂ in water, while also withstanding very high temperatures and pH. These enzymes are valuable promoters of CO₂ capturing from industrial exhaust streams. Researchers at the Biomedical Sciences Research Center Alexander Fleming (BSRC Fleming) in Vari, Greece, have identified such a bioactive molecule.

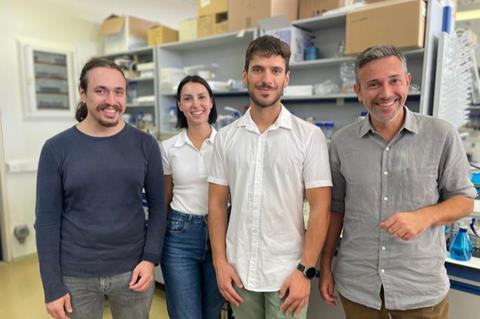

Microorganism producing resilient proteins and enzymes have evolved to thrive in extreme conditions, such as hot springs, salt lakes, and volcanoes. A team of Greek researchers, led by Dr. Georgios Skretas at BSRC Fleming developed new metagenomic analysis tools to identify a super heat-resistant enzyme of biotechnological interest.

READ MORE: Microbial enzyme captures CO2 with electricity

READ MORE: First step towards synthetic CO2 fixation in living cells

After scanning millions of genes from open-access metagenomic databases, a new promising candidate biocatalyst was found in a metagenomic sample originally collected from a hot spring in the Kirishima region of Japan. Through this process, the scientists from the Skretas Lab discovered the highly stable carbonic anhydrase CA-KR1. This robust enzyme specializes in enhancing the dissolution of CO₂ in water and exhibits unprecedented stability under industrial conditions.

Pool of proteins

“Metagenomic analysis gives us access to a “pool of proteins” that remains largely unexplored and can unravel enzymes and other proteins of great biotechnological interest, such as the CA-KR1 enzyme we have discovered,” comments Dr. Skretas. According to Dr. Skretas, the CA-KR1 enzyme is extremely stable at very high temperatures and in strong alkaline solutions, which is extremely rare for proteins.

“More specifically, the enzyme performs exceptionally well under conditions of Hot Potassium Carbonate (HPC) capture technologies, with temperatures exceeding 80 °C and pH levels above 11. It enhances CO₂ capture productivity by 90% at 90 °C compared to standard non-enzymatic methods. It also allows for 90% CO₂ removal at 80 °C, surpassing the performance of standard HPC capture and doubling the initial CO₂ absorption rate at 90 °C” explains PhD candidate Konstantinos Rigkos, who, along with the Post-Doctoral Researcher Dimitra Zarafeta, played a central role in this study, recently published in Environmental Science & Technology.

Efficient CO₂ capture

“The CA-KR1 enzyme is perhaps the most robust biocatalyst (carbonic anhydrase) for efficient CO₂ capture in HPC conditions reported to date. Its integration in industrial settings holds great promise for accelerating the industrial implementation of biomimetic CO₂ capture—a green, sustainable technology expected to be a “game changer” in carbon sequestration, significantly contributing to the timely achievement of carbon neutrality,” added Dr Zarafeta.

The innovative enzyme CA-KR1 is already patent-pending. Its transition from the laboratory bench to the industrial bioreactor will be an important step toward industrial decarbonization, significantly contributing to innovation in the critical area of CO₂ capture for the well-being of the planet. These studies are currently underway.

No comments yet