Experts from the University of Huddersfield have teamed up with an international consortium of partners for a four-year research project that aims to develop a new method for the commercial production of anti-microbial peptides (AMPs), which if successful will open up a whole new range of opportunities for the use of bio-active peptides.

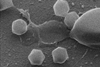

AMPs are small proteins which have delivered promising results in helping anti-infectives overcome increasing antibiotic resistance problems but have proven difficult to commercially produce.

Titled RADOV or ‘RADiation harvesting of bioactive peptides from egg prOteins and their integration in adVanced functional products’, the project has been awarded €2million from the European Union’s Euratom Research and Training Programme (EURATOM) Horizon Europe to carry out the necessary research.

Heading the team from the University is Professor Robert Edgecock from the University’s School of Computing and Engineering who revealed that AMPs have aroused great interest as potential next-generation antibiotics. Because long-term chemotherapy in cancer patients can lead to resistance to conventional cancer treatments and a susceptibility to pathogenic infection, AMPs could also become a new treatment option for cancer patients due to their antibacterial and anticancer properties.

Anti-microbial peptides

“Antimicrobial peptides (AMPs) are small proteins present in different lifeforms in nature, or that result from enzymatic digestion of proteins, which provides these lifeforms with a natural defence against microbial infections,” he said.

“In addition to the more specific antibacterial and anti-viral actions, they have shown immune-modulatory activities, antifungal actions, anti-inflammatory properties and even possess the ability to disintegrate cancerous cell membranes.”

What makes AMPs viable and important alternative antimicrobial agents, said Professor Edgecock, is the fact that the development of resistance by the microbes against the AMPs is relatively slow or delayed compared to that against conventional antibiotics.

“However, despite their promise, very few of the AMPs have been commercialised so far, mainly due to technical difficulties in their manufacture,” he said.

Methodology

To begin with, the researchers will use beams of electrons to synthesise the AMPs from egg proteins, and the results acquired regarding the peptide structure, irradiation conditions, and related bioactivity properties will become a vital output of the project.

The researchers will then use electron beam irradiation to further integrate the AMPs into two new products, peptide-laden antimicrobial/antioxidant hydrogel wound dressings and peptide-grafted active plastic foils for food packaging. This will effectively demonstrate the potential of the technique and the benefit of the antimicrobial properties of egg-derived bioactive peptides manufactured by radiation-induced fragmentation.

Co-ordinating the project is Poland’s Institute of Nuclear Chemistry and Technology, which will be assisted by the University of Huddersfield, Sweden’s KTH Royal Institute of Technology, Italy’s University of Palermo, the Italian National Research Council and Portugal’s Association of Instituto Superior Técnico for Research and Development.

Also playing a crucial role in the successful implementation of the project will be three industrial partners: Kikgel Sp. z o.o. and Dekofilm Polska Sp. z o.o. from Poland and Italy’s E.P.S. S.p.A. Egg Powder Specialists.

Topics

- AMR in the Environment

- anti-microbial peptides

- Antimicrobial Resistance

- Antimicrobials

- bioactive

- Dekofilm Polska Sp. z o.o.

- E.P.S. S.p.A. Egg Powder Specialists

- EURATOM

- Food Microbiology

- food packaging

- Food Safety & Security

- Food Science & Technology

- Food Security & Safety

- Horizon Europe

- hydrogel

- Industry News

- Kikgel Sp. z o.o.

- One Health

- proteins

- RADOV

- Research News

- Robert Edgecock

- UK & Rest of Europe

- University of Huddersfield

No comments yet