Slime build-up is a costly drag on fuel efficiency for ocean-going cargo ships, leading to more emissions and, eventually, higher consumer prices.

However, a recent study, published in the journal npj Biofilms and Microbiomes, suggests a new approach to manage this common problem. Researchers at KTH Royal Institute of Technology developed a model for estimating the speed and extent of biofilm growth, which could enable ship operators to schedule hull cleaning at optimal intervals to save on fuel consumption.

Cornelius Wittig, a PhD student in fluid mechanics at KTH, says the study offers a first-ever explanation of how shear stress interacts with biofilms over time to foster slime fouling on surfaces such as the hull of a ship.

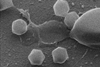

The fouling process begins with micro-colonies of bacteria attaching to a surface. These bacteria form base structures from which string-shaped streamers begin to grow. Together, the base structures and streamers combine to form surface imperfections that lead to friction between the hull and water. Streamers grow and imperfections build up at different rates depending on the level of stress induced by fluid flow against the surface.

A way to save fuel comsumption

Slime fouling adds significantly to fluid friction at sea – requiring an increase in a vessel’s shaft power by as much as 18 percent, Wittig says. “A ship covered with a thin biofilm may experience up to an 80 percent increase in fuel consumption.”

READ MORE: Carbohydrate produced by bacteria triggers marine biofouling

READ MORE: Efficient oil-eating bacteria cooperate to maximize dining capacity

In many cases a ship doesn’t get scheduled for cleaning until the operator sees a spike in fuel consumption, he says. “By then it’s too late and a lot of fuel has been wasted.”

So in order to reap the benefits of de-fouling a ship, timing is essential, he says.

“The potential fuel savings gained by cleaning need to be great enough to offset the costs of the dry-dock and cleaning procedures,” he says. “Accurate predictions would allow for efficient scheduling of cleaning for ship operators.”

Model optimisation

He says more research is needed in more realistic conditions before the model can be used in shipping. The evidence shows that shear stress can be roughly estimated just by knowing the speed of a ship.

“From a ship operator’s perspective, it is interesting to know if the ship should be cleaned in next month or next year, so an estimate is sufficient to increase the accuracy of their decision making.”

Wittig says the research can apply across a wide range of areas where biofilm is a problem, including dentistry and medicine.

“The streamers can oscillate and increase the drag experienced by a ship or in a pipe,” he says. “In smaller geometries, such as in medical devices like stents or catheters, the streamers can lead to rapid clogging.”

No comments yet