Without proper medical invention, injuries sustained from traffic collisions, serious workplace accidents or weapons may result in fatal hemorrhaging.

University of Central Florida researchers aim to prevent such bleeding in potentially deadly situations with a new hemostatic spongelike bandage with antimicrobial efficacy that they recently developed and detailed in a newly published study in the journal Biomaterials Science.

“What happens in the field or during an accident is due to heavy bleeding, patients can die,” says Kausik Mukhopadhyay, assistant professor of materials science and engineering at UCF and study co-author. “These fatalities usually occur in the first 30 minutes to one hour. Our whole idea was to develop a very simple solution that could have the hemostatic efficacy within that time. If you can save the patient, then the doctors and the nurses can then save the patient.”

Chemistry and mechanisms

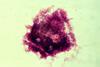

The method Mukhopadhyay and his team developed is called SilFoam as it’s more of a foam than a traditional bandage wrap. SilFoam is a liquid gel comprised of siloxanes (silicon and oxygen) that is delivered via a special two-chamber syringe which rapidly expands into a spongy foam upon exposure to each other within the wound in under one minute. The sponge applies pressure to restrict the hemorrhage at the delivery site while also serving as an antibacterial agent because of the silver oxide in it.

For every five milliliters of gel injected, you can expect an expansion of about 35 milliliters, Mukhopadhyay says.

“Anytime you have a profuse bleeding or bleeding, you want to press on top and stop the bleeding,” he says. “So, what we did here is actually the same thing. Instead of putting the hand, we injected it, and it creates a voluminous expansion.”

Gentle removal

Mukhopadhyay and his collaborators found that their sponge also resulted in a more gentle removal.

“The adhesive property of this bandage is optimized so that when you take it out from the system, the smaller vessels don’t get ruptured, but it has the right amount of addition that can adhere to the muscles, veins and the arteries so that the blood doesn’t leak,” he says.

The sponge’s porosity and adhesion properties help it expand and seal the wound, allowing the body’s natural clotting process to take over, Mukhopadhyay says.

“During the reaction, it generates a little bit amount of heat that helps the process very fast,” he says. “On top of that, oxygen gas as part of the reaction’s byproduct, tries to come out. So instead of making it a cross-linkable rubber, it’s a soft sponge with a lot of internal porosity.”

Anatomic model

Researching ways to address wounds requires special care and consideration to ensure no harm comes to test subjects, however, the researchers were able to bypass this by using a functional anatomic model to test their methods.

They used specially crafted mannequins designed with realistic blood vessels and wounds developed by a local company called SIMETRI to test their foam on in hopes the preliminary results were promising enough to proceed with further testing.

“One of the most important parts of this was that we used non-invasive models,” Mukhopadhyay says. “At this phase, we can get approvals and move forward to study the in vivo models. At this stage, there are no psychological effects on vets or surgeons either.”

Advantages over others

The experimentation showed promise, especially when the researchers compared SilFoam to five other existing treatment methods.

They found that SilFoam had many advantages such as significantly less leakage, room-temperature storage versus requiring cold temperatures, ultimately lower cost of materials, little to no training requirements to use the syringe.

Pritha Sarkar, a graduate student in the materials science department at UCF, assisted with the experimentation.

“We had to check the reactivity of the two parts, because we wanted enough oxygen gas that can expand the sponge, but at the same time, we didn’t want the material to get too hot, because the reaction itself generates heat,” she says.

Durable but not rigid

Sarkar tested the toxicity and strength of the materials as well to ensure it was safe for human bodies and durable yet not too rigid.

She also worked to make sure the composition of the SilFoam doesn’t harm the patient upon removal.

“If you have something that’s very sticky, like a bandage that you can slap onto your wound, that that will prevent blood from coming out, but if you want to remove that bandage, it can cause tissue damage or pain,” Sarkar says. “Our polymer system doesn’t stick to your skin, so it’s very easy to remove. We have a dressing that can expand onto your wound and seal it shut, but at the same time, once it’s done its job, you can remove it very easily.”

Reducing infections

The antibacterial component of the research was through Melanie Coathup, a UCF College of Medicine professor and director of the Biionix Cluster at UCF.

She works alongside material scientists and mechanical engineers with the goal of creating new medical technologies and therapies.

“My post-doc Dr. Abi Sindu Pugazhendhi and I worked alongside Dr. Mukhopadhyay and team to investigate the potency of his material and how well it stopped bacterial growth,” Coathup says. “We assessed bacteria that would typically infect a traumatic injury to the torso, and our results showed that the material was highly effective and so utilizing this material within the bandage system developed by Dr. Mukhopadhyay and confirming its efficacy as a novel hemostatic and antibacterial strategy is a great and important find.”

Rewarding opportunity

She says the opportunity to save lives as part of this research was extremely rewarding.

“The research is significant, because at the moment, there are no effective treatments available to treat people with these conditions, and new strategies are really needed,” Coathup says. “This means that teaming up with Dr. Mukhopadhyay to investigate a novel antibacterial sponge that could in the future provide life-saving treatment following major traumatic injury, was an absolute pleasure and right up my street.”

Mukhopadhyay also recently received a GAP award to assist in licensing SilFoam and deploying it. He says the next step is to collaborate with the University of Nebraska Medical Center and perform in vivo studies at their facilities.

Those interested in licensing this technology may learn more here.

No comments yet