With greenhouse gas emissions peaking, the search for renewables is intensifying. AMI Healthy Land Scientific Advisory Group member Juan Luis Ramos and his colleagues Estrella Duque and Patricia Godoy take a look at the future of biofuels.

Several international reports from the IPCC and the World Meteorological Organization have indicated that greenhouse gas emissions reached a peak (CO2 levels were 424 ppm) in 2023 and that the current overall temperature increase is 1.45 ± 0.12 °C.

Terrestrial transport accounts for up to 20 % of all carbon emissions to the atmosphere (www.eea.europa.eu). In addition, about 2.5 % of all human carbon dioxide emissions result from aircraft. It is estimated that air travel emitted around 785 million metric tonnes of carbon dioxide in 2019, equivalent to the pollution from 164 million cars. Another relevant contributor to GHG emissions is the chemical industry.

The Kyoto and Paris Protocols called for the use of clean, green, and renewable transportation fuels to replace gasoline, diesel, and jet fuel. The UN Climate Conference COP 28 held in Dubai, affirmed that anthropogenic pollution has an impact on global changes, severe droughts, wildfires and enormous floods all over the planet. In spite of calls to stop fossil-fuel emissions and signatures on protocols, the top 40 leading economies, all of which signed the Paris Accord, have failed to take the necessary steps to limit emissions, and attempts to stop carbon extraction by 2035 or the replacement of combustion cars with electric or hydrogen-powered ones seem unaffordable at present.

The current trends are to provide an energy mix favoring the use of renewable energies (solar, photovoltaic, wind, marine waves and biofuels). Biofuels for motor vehicles are considered potential alternatives for carbon emission savings because biofuels are produced through processes that significantly reduce net emissions. A number of biofuel programs have been implemented in the United States, Brazil and the European Union with the aim of not only reducing emissions, but also reducing the importation of fossil fuels and enhancing the security of fuel supply at a national level.

Despite these efforts, current estimates indicate that only about 6% of the energy used globally can be traced back to a biofuel source; therefore, there exists great opportunities to increase the use of renewable liquid fuels. For a biofuel to be a viable fuel alternative, it should provide a net energy gain, have environmental benefits, be economically competitive, and be produced in large amounts without reducing food supplies.

Currently, ethanol is the most common biofuel, with nearly 99% of its production coming from corn grain (and other cereals), and it is referred to as ‘first-generation’ (1G) bioethanol. In the United States, ethanol production rates in 2022 were in the range of 15 billion gallons per year at corn dry mills; these mills produce not only ethanol but also corn oil and dry distillers’ grains (DDG)—a product that is used as animal feed. It is estimated that the ethanol produced in the United States serves to replace about 500 million barrels of petroleum annually. Europe currently produces about 1.5 billion gallons of ethanol, and Brazil, the second-largest producer and user of ethanol, produces about 7.4 billion gallons of ethanol from sugarcane.

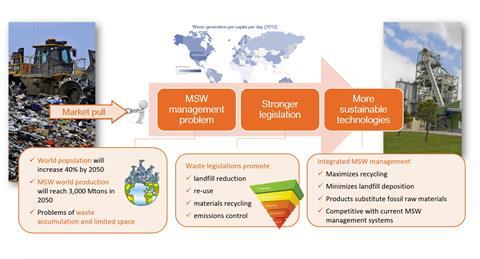

Although 1G bioethanol is recognized as a renewable energy source, its production is controversial, as it has been the subject of a wide range of societal and political debates. Questions about costs, security of energy supply, greenhouse gas emissions, sustainability of production systems, impact on food production, and biodiversity are some of the many issues that have been raised regarding this source of energy. If all the US corn were used to produce biofuels, this would only satisfy 12% of the demand for gasoline. The use of non-food sources, such as corn stover, wheat straw, woody biomass, or organic matter from municipal solid waste (MSW), known as ‘Second-generation’ (2G) bioethanol (Figure 1), is the most advanced biotechnology for production of alcohols for combustion motors.

The production of 2G bioethanol usually requires three major steps: a physicochemical pre-treatment, an enzymatic breakdown of biomass into its constituent sugars, and fermentation. Details on the process steps have been described by Alvarez et al.

At present, 2G biofuels are not cost-competitive versus 1G biofuels, mainly because of large investments in the construction of 2G plants, feedstock prices, and operational costs associated with enzymatic hydrolysis, which comprise a large fraction of the costs of producing 2G biofuels. Valuation studies by Valdivia et al. regarding 2G plants for the production of ethanol from MSW indicated that costs associated with setting up 2G plants will only diminish after several plants have been built. In the meantime, and to favor 2G biofuels being blended into gasoline, a premium price for biofuel based on a credit system known as ‘RINs’ was established in the USA.

It was estimated that advanced biofuels from MSWs could replace 16% of fuel used by the U.S. transportation sector by 2030, provided that MSWs are sustainably sourced . This biofuel could reduce greenhouse gas emissions with savings by 65%, even when taking into account all possible indirect emissions. The organic fraction of MSW is around 61% in the United States (about 50% in the UK), and according to the EPA, if the 164 million tonnes that are currently diverted to landfills in the United States were converted to bioethanol, about 7.5 billion gallons of ethanol would be produced from biowaste, representing savings of around 250 million barrels of petrol. Therefore, there is great potential for the production of biofuels from MSW residues (figure 2 and 3).

Ethanol is blended with gasoline up to 10%; this gasoline, known as E10, reduces the emission of fine particulate matter by 36%, and by as much as 65% in cars with large displacement volumes. Benzene is often identified as the most toxic and carcinogenic compound found in car exhaust, and E10 gasoline emits 25% less benzene.

Currently, debates within the biofuel field are positioning butanol as a better fuel component than ethanol since it can be blend up to 16% with gasoline. Advanced biofuels such as farnesane and others are being explored and used at low mix as jet-fuels. Other values of biofuels include their co-products for animal feed, the promotion of a large number of rural jobs, and the possibility of being implemented everywhere. Furthermore, microbes can contribute to producing chemicals (carboxylated acids, hydrocarbons, etc) that can exploit the solid groundwork developed in 2G processes.

Juan L. Ramos (corresponding author), Estrella Duque, Patricia Godoy

Estación Experimental del Zaidín. Consejo Superior de Investigaciones Científicas; c/ Profesor Albareda 1, 18008 Granada, Spain; Phone: +34 958439153; Email: juanluis.ramos@eez.csic.es; Juan L. Ramos ORCID number: 0000-0002-8731-7435.

No comments yet