For the sake of the environment and our quality of life, effective treatment of wastewater plays a vital role. A biological method to treat sewage using moving, biofilm-covered plastic items known as carriers has been gaining prominence, and an Osaka Metropolitan University-led team has found ways to make the process more efficient.

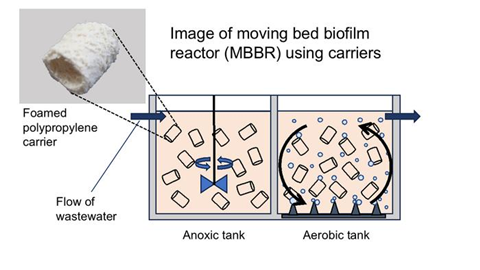

The moving bed biofilm reactor (MBBR) process purifies wastewater by putting these carriers in motion to get the biofilm’s microorganisms into greater contact with organic matter and other impurities. The more biofilm that can be attached to the plastic carriers, the more microorganisms that are available to clean the wastewater.

READ MORE: Studies explore converting wastewater to fertilizer with fungal treatment

READ MORE: Bacterial biotechnology to remove phosphorus from wastewater given funding boost

OMU Professor Masayuki Azuma and Associate Professor Yoshihiro Ojima of the Graduate School of Engineering worked with a team from Kansaikako Co., an Osaka-based company specializing in water treatment-related products, and found that polypropylene carriers foamed to create uneven surfaces and more surface area allowed 44 times more biofilm formation than smooth plastic carriers.

Waste biomass

Moreover, adding waste biomass such as composted seaweed when foaming further enhanced the performance of the foamed plastic carriers, especially in terms of nitrate removal during the MBBR process.

“Since there is a wide variety of wastewater, it will be necessary to prove that these foamed carriers also have superior suitability to various wastewater,” stated Professor Azuma. “It is clear that the addition of waste biomass improves the performance of the carriers, so we expect that further performance enhancement can be achieved depending on the additive.”

The findings were published in Environmental Technology & Innovation.

No comments yet