Researchers have pioneered a microbially driven process that utilises low-value waste products, such as magnesium mine waste and sulfur from desulfurisation plants, to leach the wastes and generate a stream of solubilised magnesium.

The research is unveiled in the paper, ’Dissolution of mining waste and semi-selective solubilization of magnesium by Fervidacidithiobacillus caldus’ , which has been accepted by the Journal of Applied Microbiology, an Applied Microbiology International publication.

READ MORE: Meet the microbes revolutionising the sustainable recovery of critical metals

READ MORE: Microbes devour mining waste, yielding resources

Metals mining generates substantial amounts of solid waste. For instance, a 2019 report assessing 3,500 of the world’s largest mining operations revealed that over 100 billion tonnes of solid waste were produced annually, highlighting a staggering gap between the production of valuable metals and waste byproducts.

Moreover, these wastes frequently pose significant environmental hazards as they are often stored in open heaps wherein, they may leach e.g., metals into groundwater. These waste heaps commonly contain heavy metals in sufficient concentrations to impact human health.

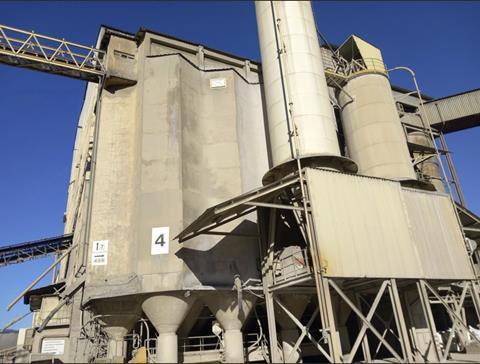

The current global footprint of mine and processing wastes is estimated to exceed 200,000 km², creating formidable challenges for management and containment. As a case in point, a single magnesium-containing mineral producing mine can stockpile up to 250,000 tonnes of waste while adding an additional 50,000 tonnes annually.

Value from waste materials

Despite these obstacles, mine wastes often include significant concentrations of economically valuable metals. In the case of magnesium-containing mineral producing mines, waste can contain as much as 30% magnesium metal by mass – a critical structural metal currently experiencing increasing demand across various applications, but primarily the aerospace and automotive industries.

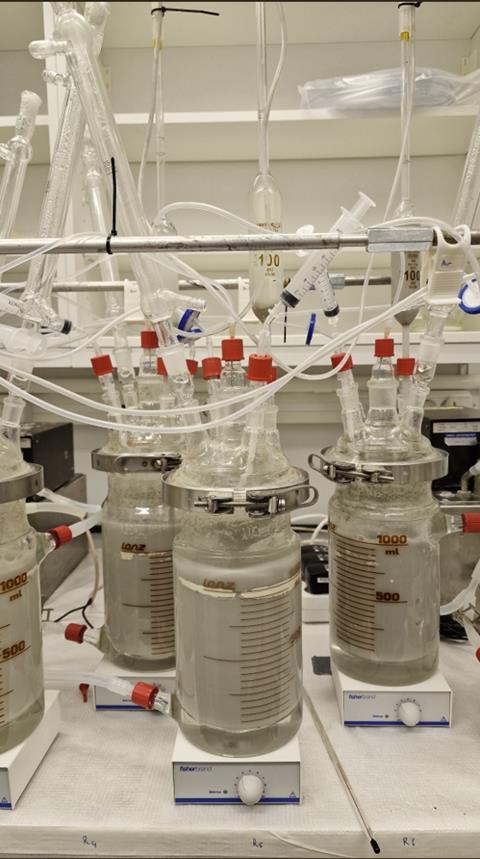

Researchers at Linnaeus University in Kalmar, Sweden, have pioneered a microbially driven process that utilises low-value waste products, such as magnesium mine waste and sulfur from e.g., desulfurisation plants, to leach the wastes to generate a stream of solubilised magnesium. This magnesium can subsequently be reintegrated into the primary mining process, thereby enhancing the yield of the primary mining process and reducing waste stored onsite.

This innovative technology enables mines to access significant magnesium deposits within waste heaps while minimising their environmental footprint, thereby reducing the volume of primary waste and lessening their ecological impact. In the context of magnesium mining, this approach has the potential to transform the industry into a more sustainable and value-driven enterprise.

’Dissolution of mining waste and semi-selective solubilization of magnesium by Fervidacidithiobacillus caldus’ appears in the Journal of Applied Microbiology.

No comments yet