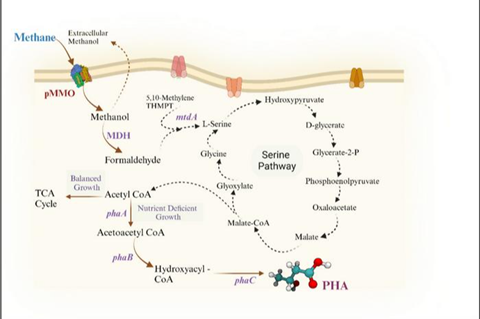

Scientists have tapped into a methane-consuming bacterium, Methylocystis suflitae, to produce biodegradable plastics called polyhydroxyalkanoates (PHAs), offering a dual win for climate and sustainability.

Through genomic analysis of the bacterium, the team discovered four distinct genes responsible for producing PHA synthase, a critical enzyme in plastic synthesis. Advanced protein modeling and molecular docking revealed how these enzymes efficiently bind substrates, with hydroxybutyrate and hydroxydodecanoate showing the strongest interactions.

READ MORE: Methanotrophs: an emerging biotechnological workhorse in the bioproduction industry

READ MORE: Towards space plastics - and solving a few Earth problems en route

The team optimized fermentation conditions to achieve a high PHA production rate of 11.90 mg/L/h, a critical advance for industrial use where low methane solubility often hampers efficiency. The resulting plastic matched commercial quality, displaying a melting point of 188°C and a distinct infrared signature confirming its structure.

Dual solution

This breakthrough not only converts methane—a potent greenhouse gas—into eco-friendly materials but also overcomes key industrial bottlenecks. Leveraging the natural adaptability of methane-consuming bacteria to low methane environments, the study opens doors to scalable, cost-effective bioplastic production, bridging the gap between waste gas recycling and sustainable manufacturing.

The work entitled “Methylocystis suflitae as a promising industrial workhorse for methane-based polyhydroxyalkanoate production” was published in Systems Microbiology and Biomanufacturing.

No comments yet