Polyethylene terephthalate (PET) is one of the most widely used plastics, commonly found in bottles, fibers, and many other products. It is a unique member of the plastic family as it can be broken down into its constituent units (or monomers) by PETases, which are enzymes that degrade PET.

Until now, scientists have discovered a variety of PETases in nature, including from bacteria, Ideonella sakaiensis, and leaf-compost cutinase. These biocatalysts have been modified for industrial applications.

Decomposing contaminated PET under mild conditions and producing high-purity monomers is currently a critical focus in plastic recycling technology, highlighting its need for more such efficient biocatalysts.

Engineering and profiling PET-degrading enzymes

Taking a major step in this direction, a team of researchers from Kyungpook National University (KNU), led by Kyung-Jin Kim, Professor of Life Science and Biotechnology and Head of KNU Institute for Microorganisms, has come up with an innovative landscape profiling method to determine the potential of naturally occurring microbial enzymes to degrade PET plastics. Their novel findings, expected to help solve the existing problems in the recycling industry, were published online the journal Science.

This study explores various aspects of this little-explored field, from landscaping of genetic sequences to screening for high-fitness enzymes, engineering them, and evaluating their performance under industrial conditions. Specifically, the researchers employed a novel clustering approach to screen around 2000 candidate enzymes across several families. This produced a view of landscape proficiency and stability in terms of the fitness of promiscuous enzymes.

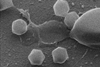

As a result, the team could identify peaks corresponding to potentially highly efficient enzymes for further testing and optimization. Subsequently, they successfully engineered enzymes Mipa-P and Kubu-P through sequential mutagenesis, which exhibited excellent performance compared to benchmarks under extreme conditions typically present in recycling applications.

READ MORE: Wastewater bacteria can break down plastic for food

READ MORE: Enzyme-embedded PLA plastic can degrade in home-compost or methanization conditions

”We were particularly excited to observe that Kubu-PM12 thrives under industrial conditions. Its ability to handle high PET loads and withstand elevated temperatures, coupled with its impressive activity at lower temperatures, is highly advantageous. This makes it a promising candidate for real-world applications.” Prof. Kim exclaims.

Future of PET recycling

According to Prof. Kim, the future of plastic recycling technology is bright with the present innovation. “The novel enzymes discovered through this method will enable the continuous recycling process of PET at lower temperatures and higher productivity.

Furthermore, this landscaping method of protein sequences proposed in this study may allow for the classification categories of the chaotic enzyme family to be established in detail, which will allow scientists to more easily predict and understand enzyme function. As biocatalytic recycling becomes industrially viable, it will be possible to offset the growing demand for virgin PET from crude oil through fully closed PET recycling.” shares Prof. Kim.

No comments yet