In a recent breakthrough, researchers have utilized a one-step TAT method to fabricate bacterial cellulose (BC) macrofibers with exceptional strength and moisture responsiveness, paving the way for eco-friendly advanced materials.

In a significant advancement for sustainable materials, a team of international researchers has reported a novel approach to crafting bacterial cellulose (BC) into macrofibers (MFs) with remarkable mechanical properties and the ability to respond rapidly to changes in humidity.

READ MORE: Researchers find new way to turn bacteria into cellulose-producing mini-factories

READ MORE: Plastic-free vegan leather that dyes itself grown from bacteria

The study, led by Yadong Zhao and Zheng Yang from Zhejiang Ocean University, with contributions from researchers at Xi’an Jiaotong University and the University of Sydney, introduces a user-friendly tension-assisted twisting (TAT) technique to align BC nanofibers, resulting in MFs with impressive tensile strength and elasticity.

Stretching and aligning

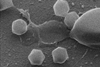

The TAT technique stretches and aligns BC nanofibers that are pre-arranged in hydrogel tubes, forming MFs with compactly assembled structures and enhanced inter-fiber hydrogen bonding. This innovation not only achieves a record tensile strength of 1,057 MPa but also equips the MFs with the ability to quickly respond to environmental moisture, generating torsional actuation with a peak rotation speed of 884 revolutions per minute per meter.

The research demonstrates that the as-prepared BC MFs have exceptional lifting capacities, with the thinnest MF2 strand lifting more than 340,000 times its own weight. This level of performance is unmatched by most cellulose-based MFs, including natural, regenerated, and nanocellulose-derived MFs.

Rapid and intense

The MFs’ humidity-responsive actuation was found to be rapid and intense, making them ideal for applications beyond actuators, such as remote rain indicators, intelligent switches, and smart curtains. The fibers’ ability to untwist upon exposure to water vapor and return to their original state after drying showcases their potential for use in moisture-triggered devices.

The study concludes that the TAT technique is a feasible method for manufacturing high-performance MFs from BC, offering a pathway to sustainable, high-strength, and functional macrofibers for various industries. This innovation aligns with global efforts towards environmental sustainability and the development of renewable materials.

No comments yet