In a significant advancement for sustainable materials science, a team of researchers from Universidad ICESI in Colombia has developed a novel approach to understanding the properties of mycelium-based biocomposites. Published in the Journal of Bioresources and Bioproducts, the study introduces a multiscale methodology that integrates microscopic analysis of lignocellulosic and fungal biomasses to comprehend their macroscopic physical and mechanical properties.

Led by Isabel Enriquez-Medina and colleagues, the research focused on the Colombian native strain Ganoderma gibbosum, cultivated on peach palm fruit peel flour and sugarcane bagasse wet dust. These agro-industrial residues were used to produce biocomposites through solid-state fermentation, a process that leverages the natural ability of fungi to break down and assimilate lignocellulosic biomass.

Biocomposites with customized properties

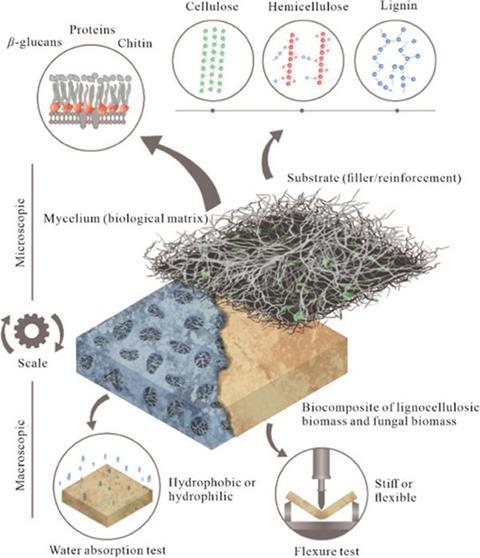

The study’s innovative approach involved monitoring substrate composition changes, such as glucan, arabinoxylan, and lignin, using biomass compositional analysis. The resulting biocomposites were then characterized through flexural and water absorption tests. The findings indicated that G. gibbosum primarily degraded polysaccharides in the media, with significant lignin degradation observed only in the mixture biocomposite, leading to a reduction in glucan and arabinoxylan weights.

READ MORE: From fungi to fashion: mushroom eco-leather is moving towards the mainstream

READ MORE: Fungal structures could be deployed in aerospace industry

The research highlights the potential of tailoring nutrient composition by designing culture media to obtain physical-mechanical properties according to specific application requirements. This could enable the production of biocomposites with customized properties, aligning with the growing demand for sustainable and renewable materials in various industries.

The study’s conclusions underscore the importance of understanding the relationship between the microscopic scale of agro-industrial waste constituents and the macroscopic behavior of biocomposites. This knowledge can inform the design of more efficient and sustainable bio-based materials, contributing to the circular economy and reducing reliance on nonrenewable resources.

No comments yet