Researchers from The Novo Nordisk Foundation Center for Biosustainability (DTU Biosustain) have developed an innovative fermentation process that produces natural betalain-type food colours.

This groundbreaking technology is set to revolutionize the food colour industry by offering a more sustainable and efficient alternative to traditional extraction methods.

Betalanins, which give red beets their distinctive hue, are commonly used worldwide in products ranging from meat substitutes to candies and ice creams. The most recognized of this group is betanin – a pigment that up until now is sourced from red beets. But the concentration of betanin in red beets is at aprox 0.2 % of the wet weight. This low content makes traditional extraction methods very wasteful.

Revolutionary process

“What’s truly revolutionary about our process is not just its sustainability and potentially lower cost, but also that you can obtain a product at a higher purity. While the beetroot extract contains sugars at high concentrations, our fermented product can be made sugar-free and thus can be made more concentrated. Furthermore, the current process presents a platform from which we can expand to making other betalanin-type colours, which are currently too expensive to be extracted from plants,” says Professor Irina Borodina.

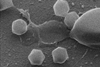

The research group at DTU Biosustain, supervised by Prof. Borodina, used an oleaginous yeast commonly found in cheese, Yarrowia lipolytica, to achieve this feat. The team performed metabolic engineering to optimize the cellular metabolism, ensuring enhanced color production and reduced by-products, thereby averting undesirable browning.

World´s demand

As part of the research project, researchers from the Sustainable Innovation Office at DTU Biosustain, provided a comprehensive life cycle assessment of the new fermentation process:

“Our findings indicate that the fermentation-based process uses significantly fewer resources, energy, and land when compared to traditional betanin extraction from beets. In effect, if we harness the potential of this fermentation-based colour production fully, we can satisfy the world´s demand with just one-tenth of the equivalent land area,” says Dr. Sumesh Sukumara.

Further techno-economic evaluations indicate that fermentation-produced betanin could well be a feasible alternative in today’s market conditions. This opens up the potential for a broader palette of natural food colours, which are both more sustainably produced and potentially more affordable.

This groundbreaking new technology holds immense promise for various industries, including biotech, food colour manufacturing, metabolic engineering, and TEA/LCA professionals.

No comments yet