Scientists at Nanyang Technological University, Singapore (NTU Singapore), have developed an innovative solar-powered method to transform sewage sludge — a by-product of wastewater treatment — into green hydrogen for clean energy and single-cell protein for animal feed.

Published in Nature Water, the sludge-to-food-and-fuel method tackles two pressing global challenges: managing waste and generating sustainable resources. This aligns with NTU’s goal of addressing humanity’s greatest challenges, such as climate change and sustainability.

The United Nations estimates that around 2.5 billion more people will be living in cities by 2050. Along with the growth of cities and industries comes an increase in sewage sludge, which is notoriously difficult to process and dispose of due to its complex structure, composition, and contaminants such as heavy metals and pathogens.

READ MORE: Biorefinery innovation: Transforming waste into high-value products

READ MORE: Hidden threats to soil revealed in sewage sludge research

According to UN-Habitat, more than 100 million tonnes of sewage sludge are generated globally each year, an amount that is increasing annually. However, common disposal methods - such as incineration or landfill - are time-consuming, energy-inefficient, and contribute to environmental pollution.

Three-step process

To tackle the problem of unwanted and difficult to treat sewage sludge, NTU researchers created a three-step solar-powered process that integrates mechanical, chemical, and biological techniques.

Proof-of-concept tests revealed that the NTU team’s process is more efficient than conventional techniques like anaerobic digestion - through which bacteria break down organic waste to produce biogas and nutrient-rich residue. It recovers significantly more resources, completely removes heavy metal contaminants, has a smaller environmental footprint, and offers better economic feasibility.

Lead researcher Associate Professor Li Hong from NTU’s School of Mechanical and Aerospace Engineering (MAE) and the Energy Research Institute @ NTU (ERI@N) said, “Our method transforms waste into valuable resources, reducing environmental damage while creating renewable energy and sustainable food. This exemplifies the circular economy and contributes to a greener future.”

Co-lead researcher Professor Zhou Yan from NTU’s School of Civil and Environmental Engineering (CEE) and Nanyang Environment and Water Research Institute (NEWRI) said, “Our solar-powered process demonstrates how we can tackle multiple challenges at once – turning a difficult waste product into clean energy and nutritious protein. By integrating mechanical, chemical, and biological approaches, our method has successfully addressed pollution and resource scarcity, offering a new sustainable strategy in wastewater management.”

How it works

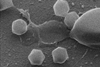

The process begins by mechanically breaking down the sewage sludge. A chemical treatment separates harmful heavy metals from organic materials, including proteins and carbohydrates.

Next, a solar-powered electrochemical process uses specialised electrodes to transform the organic materials into valuable products, such as acetic acid — a key ingredient for food and pharmaceutical industries — and hydrogen gas, a clean energy source.

Finally, light-activated bacteria are introduced to the processed liquid stream. These bacteria convert nutrients into single-cell protein suitable for animal feed.

Eco-friendly, cost-effective and scalable

Lab tests showed the new method recovers 91.4 per cent of the organic carbon in sewage sludge and converts 63 per cent of the organic carbon into single-cell protein without producing harmful by-products. In comparison, traditional anaerobic digestion typically recovers and converts around 50 per cent of organic materials in sewage sludge.

The solar-powered process achieves an energy efficiency of 10 per cent, generating up to 13 litres of hydrogen per hour using sunlight, which is around 10 per cent more energy efficient than the conventional hydrogen generation methods.

The NTU process reduces carbon emissions by 99.5 per cent and energy use by 99.3 per cent compared to traditional methods. It also eliminates harmful heavy metals from the sludge, which would otherwise be disposed without proper treatment, making the process an environmentally friendly choice.

Valuable resource

First author, Dr Zhao Hu, Research fellow at School of MAE, said, “We hope that our proposed method shows the viability of managing waste sustainably and shift how sewage sludge is perceived — from waste to a valuable resource that supports clean energy and sustainable food production.”

The NTU research team added that while the newly developed process is promising, more studies are needed to determine if it can be scaled up. A key challenge is the cost of using an electrochemical process to completely break down organic materials and extract all heavy metals from waste. Additionally, designing a complex system for a wastewater treatment facility adds to the difficulty.

No comments yet