Researchers have discovered how microorganisms such as baker’s yeast respond to a clumpier environment when a process scales up from a lab to a bioreactor, providing an insight into why the transition often fails.

As part of a multinational research project, scientists from the Institute of Biochemical Engineering of the University of Stuttgart uncovered how baker’s yeast adapt their gene expression programme in an industrial bioreactor setting.

Industrial bioprocess development often suffers from unexpected performance losses of a given microorganism (MOs) when the process strategy is transferred from the lab to the production environment.

During the scale-up, the MOs are sequentially cultivated in reaction volumes increasing by several orders of magnitude. Perfect mixing becomes increasingly challenging to achieve, causing the formation of a heterogeneous reaction space, which is opposed to the perfect homogeneity in which the process was initially developed within the lab.

These performance losses - sometimes reaching a level that can render a process inviable - are caused by the MO’s ability to sense and adapt to a changing habitat.

If these adaptation efforts go hand-in-hand with sacrifices in production capabilities, bioprocess engineers speak of “scale-up effects”.

The experiment

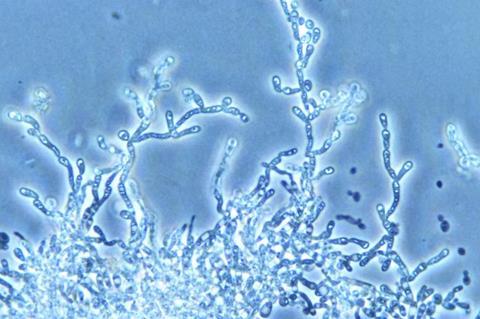

In this study, ‘Performing in spite of starvation: How Saccharomyces cerevisiae maintains robust growth when facing famine zones in industrial bioreactors’, the researchers imposed typical heterogeneities on growing baker’s yeast cells that were already in the lab-scale to characterize scale-up effects on a gene-expression level.

The cells were exposed to a dynamic glucose profile in a 1L bioreactor by intermittently supplying the substrate. This strategy was chosen to represent how a yeast cell experiences an unequal substrate availability as it travels through a 60 m³ tank during fermentation.

Gene regulation dynamics were uncovered using next-generation sequencing and provided two main conclusions.

Firstly, when cells experience the heterogeneities for the very first time, they trigger a global stress response programme, which is eventually retraced.

Secondly, when the cells adapt to the environment in the long run, their internal resource management changed to strengthen their internal growth capacities by increasing the ribosome abundance.

Together, these scenarios can help scientists to understand performance losses during scale-up and to propose strain engineering targets to construct more robust strains.

The next step of the project will involve studying the beneficial effects of these engineering propositions.

The study was published in Microbial Biotechnology, an Applied Microbiology International publication, in 2022 and was part of the PhD program of Steven Minden in the work group of Prof. Ralf Takors.

Embedded in a project consortium between the University of Stuttgart, TU Delft, University of Liege, DSM, Centrient Pharmaceuticals and Syngulon, the authors received funding from ERA CoBioTech/EU H2020 (grant 722361) and the German Federal Ministry of Education and Research (grant number: FKZ 031B0629).

Topics

- Applied Microbiology International

- bioreactor

- Centrient Pharmaceuticals

- Community

- fermentation

- Laboratory Services

- Microbial Biotechnology

- Microbial Genetics

- Professor Ralf Takors

- Research News

- Saccharomyces cerevisiae

- scale-up

- Steven Minden

- Syngulon

- UK & Rest of Europe

- University of Liege

- University of Stuttgart

- yeast

No comments yet