It is one of the most important enzymes in medical diagnostics: horseradish peroxidase is used for many medical products and it is often used when a colour change of a test strip is needed to detect the presence of antibodies or other proteins.

Recently, however, there has been a shortage of horseradish peroxidase, because it is obtained from horseradish roots, and this has major disadvantages. The agricultural yield is not always the same, and the roots produce not just one version of the enzyme, but a whole family of similar enzymes, in varying amounts.

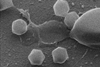

For this reason, scientists at TU Wien decided to develop a reliable, precise synthesis method in the laboratory. After years of research, they have now succeeded - the production of horseradish peroxidase is now possible with the help of E. coli bacteria.

Only one specific enzyme is produced in a precisely reproducible manner, and the process can be scaled up to large-scale industrial production. Two patents have already been applied for, and TU Wien is now looking for industrial partners.

Unpredictable vegetables

“When you extract horseradish peroxidase from plants, you don’t get a chemically well-defined substance,” says Prof. Oliver Spadiut from the Institute of Chemical, Environmental and Bioscience Engineering at TU Wien.

“Depending on the environmental conditions, the plant produces different amounts of different enzymes.”

For certain medical applications, such substances cannot be used at all – for example, it would be absolutely irresponsible to inject such a mixture of different enzymes into a human being.

In medical diagnostics, the rules are less strict, and horseradish peroxidase is used for Western blots or ELISAs. In these techniques, certain antibodies are coupled to the enzyme. The antibody docks onto a specific molecule, and the enzyme then initiates a color change. In this way, the presence of certain molecules can be made visible.

Worldwide shortages

“We are currently experiencing shortages of this enzyme worldwide,” says Oliver Spadiut. “One of the reasons for that is climate change and poor harvests. When environmental conditions change, the plant also changes the composition of the enzymes produced in ways that are difficult to predict.”

At the same time, however, global demand is increasing - the market volume for horseradish peroxidase trade is estimated to reach more than 90 million euro per year in the next few years.

Oliver Spadiut and his team therefore set out to develop a recombinant production process for the valuable enzyme. The gene for the production of horseradish peroxidase was inserted in the laboratory into yeast cells, mammalian cells and E. coli cells. All three hosts actually produced the desired enzyme, but the best technical solution proved to be the use of E. coli - a well-known bacterium that has also been used in biotechnology with great success many times before.

Unravelling the protein

However, this does not directly yield a functional enzyme, but rather a so-called ’inclusion body’ - a protein that is biochemically identical to the desired enzyme, but is geometrically folded differently.

In a further step, therefore, the inclusion body must be unravelled and then folded into the correct shape, similar to unwinding a ball of wool and then rolling it up into a well-ordered ball.

Especially in this field of research, the processing of inclusion bodies, Oliver Spadiut’s team has a lot of experience and for the first time ever, TU Wien succeeded in developing a reliable, reproducible process for the production of horseradish peroxidase. Patents have already been filed, and the process is ready.

Ready for scale-up

“We could start applying the method on an industrial scale tomorrow,” says Oliver Spadiut. “We don’t just have a theoretical concept here, but a proven method that is ready for industrial application.”

Now that it has been possible to produce horseradish peroxidase in a precisely defined, highly pure manner, this means that completely new applications beyond diagnostics are now conceivable.

“For example, one could now also use horseradish peroxidase for cancer therapy by coupling it to antibodies, which then dock very specifically to cancer cells,” says Oliver Spadiut. “We therefore expect that the market volume of horseradish peroxidase could even increase dramatically with many new applications.”

Spadiut now wants to hold talks with interested pharmaceutical companies in order to initiate the technological application of the new invention as quickly as possible.

No comments yet