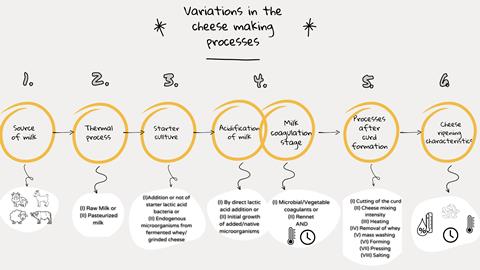

Cheese is a protein-fat concentrate produced by coagulating the milk casein followed by whey separation. Although this process is similar for all types of cheese, it is possible to produce different cheeses (Figure 1) due to differences in numerous conditions during production.

There is a great diversity of cheeses produced worldwide, from artisanal to industrial productions. These cheeses have specific tastes, aromas, and textures and consequently attract the attention of different consumers.

In industry, cheeses are mainly produced with starter cultures added to pasteurized milk. Most processes are automated and carried out with a high level of technology, ensuring greater standardization of the final product. Moreover, cheeses from industrial production are expected to have greater traceability and be evaluated according to strict quality control parameters. On the other hand, artisanal and traditional cheeses are mainly produced from raw milk and use more rudimentary, manual processes, including the use of wooden instruments. These cheeses are characterized by variations in sensory profile and chemical composition, commonly associated with the local terroir, and sometimes have a designation of origin or geographical indication.

Microbiological concerns faced in cheese-making environments are due to the excessive handling required to obtain the final cheese and the potential contamination of these products. This is especially relevant in the early stages of production and is due to the absence of barriers capable of controlling the growth of undesirable microorganisms in milk and curd. Furthermore, biofilm formation is a common risk, especially in instruments used during cheese production due to their designs that make proper sanitation difficult. Milk pasteurization can be considered an important barrier to limit the contamination by pathogens in cheese, ensuring 5D reduction of these microorganisms. However, cheeses produced from pasteurized milk may be more susceptible to post-contamination due to the absence of a competitive microbiome.

Finally, ripening helps to reduce the overall cheese contamination, as the growth of lactic acid bacteria results in a pH decay and the production of bacteriocins. In addition, at this stage, the water activity of the cheeses decreases, and the salt concentration increases, also contributing to the reduction of pathogens. On the other hand, these changes favor the growth of other contaminants, such as molds and yeasts.

Microbial ecology in cheese

Microorganisms are crucial to the development of the sensory properties of the many cheese varieties we have around the world. Beneficial microorganisms also contribute to the microbiological safety of the product due to the production of antimicrobial compounds such as organic acids and bacteriocins.

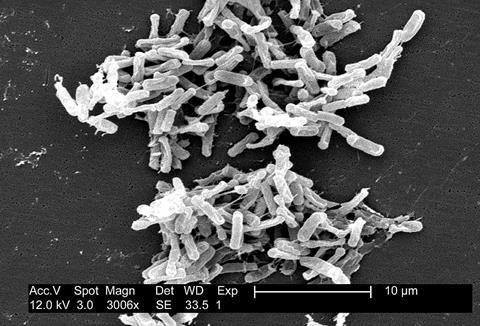

During cheesemaking, there are several types of microorganisms that are added or contaminate the milk or the cheese, and the right balance of these organisms will dictate the fate of the cheese. Commercial starter cultures, which are Lactic Acid Bacteria (LAB), are known as primary starters. These LAB are intentionally added to milk to promote fermentation and cause milk acidification, contributing to curd formation. Most starter cultures convert lactose to lactic acid, accelerating milk coagulation in addition to inhibiting pathogens. Starter cultures are usually classified as mesophilic, with an optimal growth temperature of 25°C to 30°C, and thermophilic, growing best between 40°C and 45°C. Examples of mesophilic starter organisms include Lactococcus lactis, subspecies lactis, and cremoris, as well as Leuconostoc spp. strains.

Thermophilic starter cultures generally consist of Streptococcus thermophilus strains, typically employed in the production of cooked semi-hard and hard cheeses. Additionally, members of the genus Lactobacillus, such as Lactobacillus helveticus, Lactobacillus delbrueckii, and Lactobacillus bulgaricus are often used as starter cultures. Another important group of organisms defined as secondary or adjunct cultures is composed of non-starter LAB (NSLAB) but can also include yeasts and molds. These are intentionally added to milk or cheese curd, as seen in blue cheese with the fungus Penicillium roqueforti, and in brie or camembert with Penicillium camemberti, to aid in the ripening process.

Another group is adventitious secondary cultures, which include organisms that can contaminate milk or cheese during the different production stages. These contaminants can be beneficial and contribute during ripening, influencing sensory characteristics like texture, flavor, and appearance, but can also be associated with defects, including off-flavors. Examples of adventitious cultures include Lactiplantibacillus plantarum, Lacticaseibacillus casei, Enterococcus durans, Enterococcus faecalis, Pediococcus acidilactici, Pediococcus pentosaceus, and Leuconostoc mesenteroides. These microorganisms are essential for the uniqueness of each cheese variety, as they contribute to the distinct aromas and flavors associated with the metabolites they generate.

Artisanal or traditional cheeses (terminology varies by country) are typically made with raw milk, and many producers use non-commercial, undefined starter cultures, such as raw milk itself, fermented whey, or grated cheese. Many of these producers, including a great portion of artisanal cheese producers in Brazil, use the back-slopping technique in which the drained fermented whey from the previous day´s production is used to inoculate a new batch, and this process is repeated daily.

Raw milk cheeses are usually appreciated for their rich sensory attributes and many consumers seek these products due to their stronger sensory appeal. However, spoilage and pathogenic organisms can also contaminate the cheese, causing defects or even posing health risks due to foodborne illnesses. These undesired organisms are contaminants that arise from improper hygiene practices during any stage of production. Some typical defects caused by spoilage organisms can be exemplified by the ’early-blown defect’ caused by coliform bacteria and the ‘late-blown defect’ caused by bacteria of the genus Clostridium. These contaminants may come from raw milk due to mastitis or improper cleaning of the animal´s teat, milking equipment and pipes, food handlers´ hands, tanks, water, surfaces in the dairy, cross-contamination, and silage, among others.

Pathogens in cheeses and the risks to public health

Pathogenic bacteria in cheeses can pose significant public health risks, especially when cheeses are made from unpasteurized milk, have no or short ripening periods, and when proper hygiene practices are not followed. It is important to emphasize that cheese provides a conducive environment for the growth of microorganisms. Therefore, all necessary measures should be taken to prevent product contamination, as many pathogenic organisms can survive under the harsh conditions commonly found in some types of cheese, including high salt content, low water activity, and low pH.

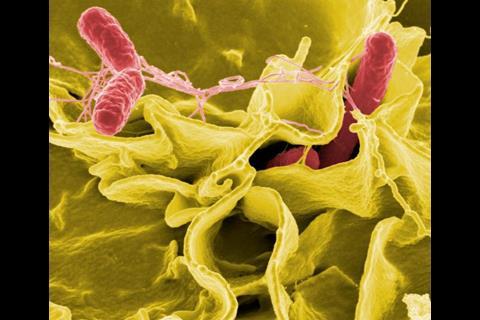

The key microbial pathogens associated with cheeses are Listeria monocytogenes, Salmonella spp, enterotoxigenic Staphylococcus aureus, and some lineages of Escherichia coli.

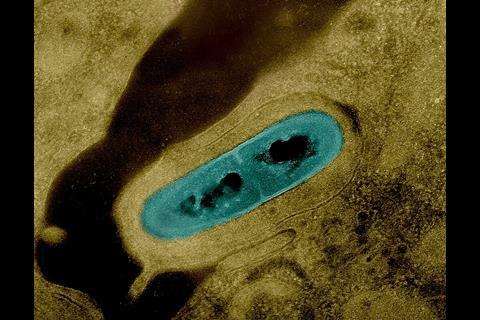

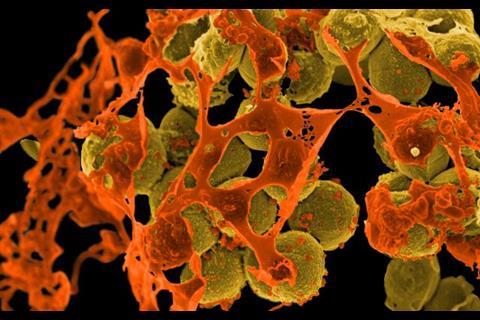

L. monocytogenes is a ubiquitous organism, often found in soft cheeses, especially those made from unpasteurized milk. It can cause listeriosis, which is particularly dangerous for pregnant women, newborns, the elderly, and immunocompromised individuals. Symptoms include fever, muscle aches, and gastrointestinal issues, which can lead to severe complications like septicemia, meningitis, abortion, and death. The organism is known for its ability to grow at low temperatures and persist in dairy environments in the form of biofilms if proper hygiene measures are not followed.

Salmonella spp can contaminate any type of cheese, particularly through cross-contamination or improper handling. However, most outbreaks of salmonellosis associated with cheese are linked to the use of raw milk in production, particularly in soft, unripened cheeses. The pathogen can cause diarrhea, fever, and abdominal cramps. These symptoms are particularly severe in vulnerable populations.

S. aureus is often found on the skin of animals and humans and can contaminate cheese through improper handling and milking. Several strains are capable of producing toxins that can cause food poisoning, leading to symptoms such as vomiting, nausea, and diarrhea. High counts of S. aureus have been observed in many types of artisanal cheeses, particularly in Brazil, but regulation varies between countries. For instance, in the European Union, populations reaching up to 5 log CFU/g are allowed, while in Brazil the maximum count of Coagulase Positive Staphylococcus (CPS - mostly composed of S. aureus) is only 3 log CFU/g. Enterotoxin production presumably only occurs when the population of CPS is higher than 6 log CFU/g. Despite the high incidence of S. aureus in cheeses, the number of reported outbreaks due to this organism in cheese is low.

Despite being common in the human and animal gastrointestinal tract and frequently found in the environment, some lineages of E. coli, particularly the Shiga toxin-producing E. coli - STEC, can cause severe abdominal cramps, diarrhea (often bloody), and vomiting. In some cases, they can cause hemolytic uremic syndrome (HUS), a serious condition that can lead to kidney failure, particularly in vulnerable populations like children and the elderly. There have been some outbreaks caused by STEC due to the consumption of raw milk cheeses.

The contamination of cheeses with pathogenic microorganisms can occur at various stages, from milk production to cheese processing and distribution. Many artisanal cheeses are made from raw milk, which is at higher risk for harboring pathogens. The safety of these cheeses largely depends on the production practices and hygiene standards. By understanding the risks associated with pathogens in cheeses and implementing good agricultural and manufacturing practices, in addition to having a proactive food safety culture, producers can help ensure the safety of cheese products.

The risk of consumption of cheese with molds

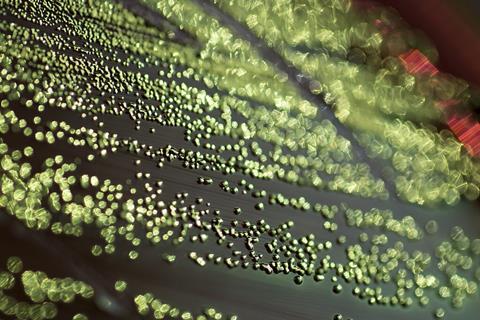

Fungi can grow on cheese, impacting quality, altering appearance and flavor, and posing health risks through mycotoxin production. Common contaminating species, including those from the genera Aspergillus, Chrysosporium, Cladosporium, Fusarium, Penicillium, Mucor, Scopulariopsis, Verticillium, and Torrubiella, are frequently identified in milk and cheese samples.

Certain cheese varieties introduce filamentous fungi to enhance the sensory qualities during ripening, notably Penicillium camemberti and Penicillium roqueforti. While these fungi can produce mycotoxins (cyclopiazonic acid from P. camemberti, and roquefortine C and mycophenolic acid from P. roqueforti), the levels of these metabolites are typically low in cheese. These fungi are generally considered safe (GRAS).

The mycotoxins of most significant concern in cheese are aflatoxin M1 and ochratoxin A (OTA), primarily due to their stability and toxicity. The Aspergillus section Flavi species are the primary sources of aflatoxins (AFs), which can contaminate cheese directly through fungal growth or indirectly through milk from dairy animals that have consumed feed contaminated with aflatoxin B1. In these animals, aflatoxin B1 is metabolized into aflatoxin M1, which is then excreted in their milk. Aflatoxin B1 is known to cause liver damage and is classified as a group 1 carcinogen by the International Agency for Research on Cancer (IARC). Ochratoxin A (OTA), can be produced mainly by Aspergillus ochraceus, Aspergillus westerdijkiae, Aspergillus steynii, Aspergillus carbonarius, Aspergillus niger, Penicillium verrucosum and Penicillium nordicum. OTA is associated with kidney damage, as well as liver necrosis and enteritis. Other mycotoxins, such as mycophenolic acid, patulin, citrinin, PR toxin, and sterigmatocystin, have been evaluated in cheeses but are rarely found.

Some external and internal factors can directly interfere with a fungi’s presence and mycotoxin production in cheeses. External conditions include temperature, oxygen availability, and relative humidity. Internal conditions include water activity, pH, and interactions between microorganisms in the cheese microbiota.

One primary source of contamination by toxigenic fungi is the ambient air in production areas. Airborne fungal spores can contaminate raw materials, surfaces, and utensils used during cheese production and germinate, leading to mycelial growth during ripening. Additionally, milk poses a risk, for cheese produced with raw milk or even for those produced with pasteurized milk, as some fungal spores resist high temperatures and can remain viable. In some cases, brine used in cheese production can also act as a reservoir for fungal spores, including species such as Penicillium commune.

Despite advancements in understanding the factors contributing to fungal development, undesirable fungi during the cheese ripening process remain a significant concern for artisanal cheese producers. Fungal spores found in the cheesemaking environment attach themselves to the cheese rinds, multiply, and proliferate, forming several colonies of filamentous fungi and yeasts to which their vegetative or reproductive structures are exposed. These fungi on the cheese rinds bring a unique sensory aspect. Cheeses with these characteristics are known as “artisanal cheeses with bloomy rinds” and are currently highly sought after and valued nationally and internationally. However, some toxigenic fungi may be present, producing mycotoxins, and cheese producers generally cannot recognize these fungi.

Further research is essential for identifying fungal species that can direct better management strategies in artisanal cheese production. Additionally, developing quick and efficient methods for detecting mycotoxins, such as aflatoxin M1 and ochratoxin A (OTA), is crucial to ensure the microbiological safety of these products and protect consumer health.

Strategies to mitigate risks in cheeses

Microorganisms are essential to the development of the desired sensory characteristics in cheeses. However, pathogens may have access to the product from the early stages of production, all the way through to consumption. At the farm, good agricultural practices will ensure the quality and safety of milk. Management of animal health and milking practices that prevent mastitis are crucial. At the cheese factory, good manufacturing practices which include following strict hygiene protocols and food handlers´ health, aligned with the proper use of starter cultures and ripening conditions will ensure the product remains free of dangerous organisms. At retail, good storage conditions, in addition to good handling practices, particularly when products are sliced and repacked before commercialization, will keep the cheese from cross-contaminating with undesirable organisms from the environment.

Consumers should follow basic food safety guidelines at home to prevent cheese contamination. Those who are immunocompromised, such as individuals with weakened immune systems, should avoid certain high-risk products like fresh and soft cheeses, as they are more prone to contamination by L. monocytogenes. It is also important that product labels clearly indicate if the cheese is made from raw milk, emphasizing the potential risks. Ensuring proper labeling and understanding the specific risks associated with certain cheeses can help protect vulnerable consumers from foodborne illnesses.

No comments yet